Various technologies, one partner

Reduce costs and deadlines by anticipating the future >

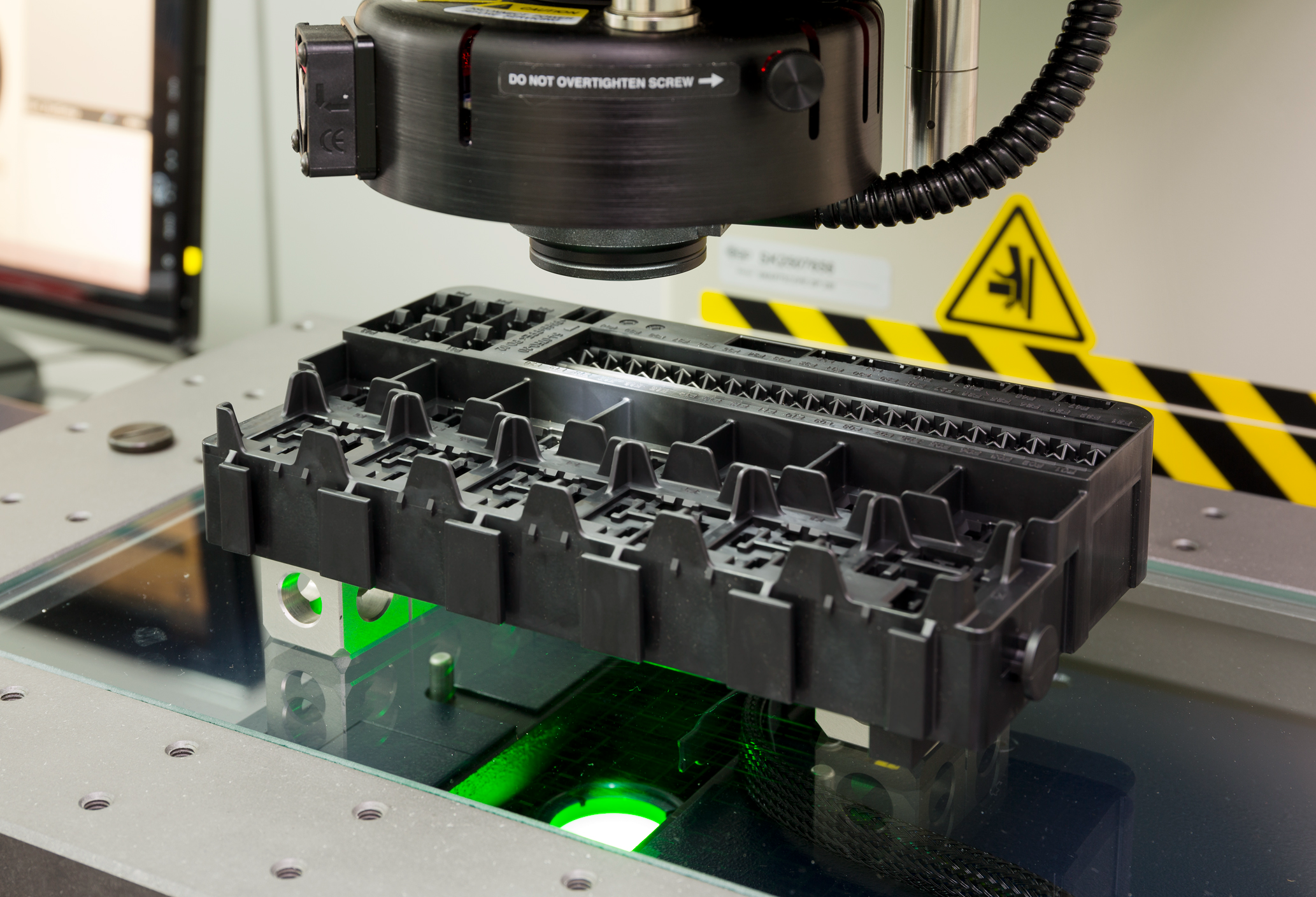

Test your parts before the mold is produced avoiding changes to the project at a later stage, thus avoiding additional costs and extending the execution time.

Along with the mold preliminary drawing we provide a set of parts for assembly and function testing.

Various technologies, one partner >

The manufacture of molds is a real technical challenge and our company's expertise guarantees - at all stages of the process - total quality, using work methodologies where communication is essential.

More than two decades of experience and excellent results have given us the ability to manage the production of any type of plastic injection molds: with 2 components, gas injection, stackmold and Tandem mold, among others; whatever the dimensions and with the highest precision, our molds are the solution that optimizes timings and presents the best performances.

Projects where several technologies are needed, the interlocutor/partner is just one, Santos & Schulz.

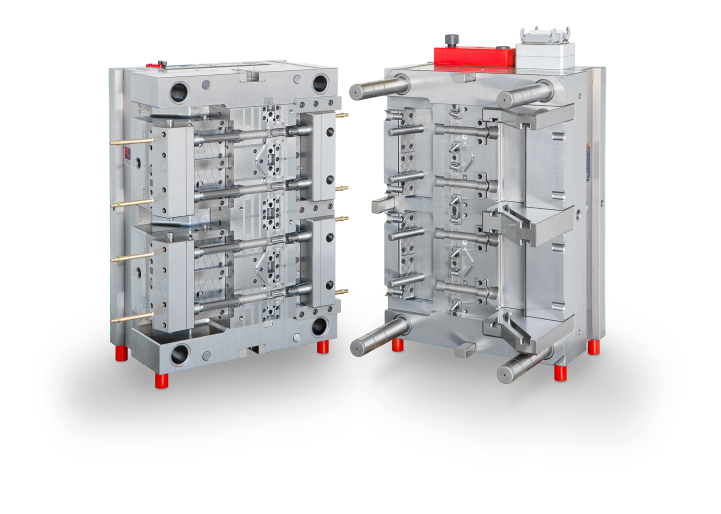

Faster and cost-effective: TANDEM-MOLD >

We are specialists in Tandem molds, a concept that allows a drastic reduction of up to 40% in costs without loss of quality and increasing the speed of production. These advantages are highly competitive when you want to inject different parts into the same mold, with optimized timings.

The Tandem molds have 2 parting lines, which open alternately: while the machine opens for the demoulding of one parting line, the second is firmly closed by a Locking System.

For more information on Tandem molds, please visit T / Mould